Shuttle ECO - Wasserbauer

- Modular feed kitchen with storage boxes (ports)

- Flexible working hours because several days' basic ration is already prepared

- Clean and effective storage hoppers, no feed residues, so there is no additional cleaning work

- No feed remnants, less picky feed consumption, forage is already chopped in the storage boxes

- All components are weighed precisely by the feed kitchen and in the mixer

- Uniform metering by scales, which controls the speed of the mixer and opening of the mixer flap

- Rapid return on investment thanks to low power consumption and labour saved

- Consistent and individually adjustable feed rations

- Fresh feed rations several times a day appropriate to each group of animals

- Fresh feed presented several times a day has a positive effect on the natural feeding behaviour of the animals and also leads to a more efficient feed usage

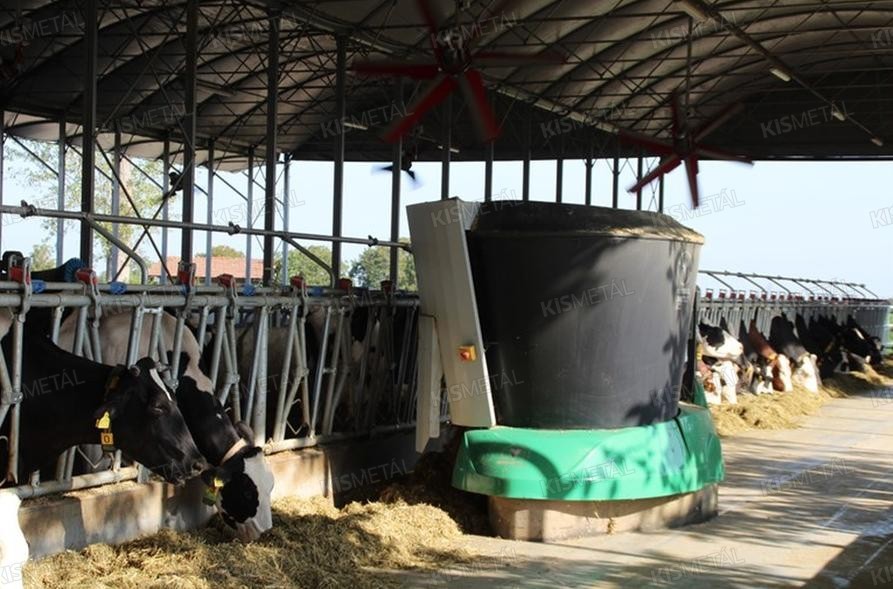

Application: Autonomous feeding robot that holds 2.2 m³

Dimensions: 2450 x 1730 x 2050 mm

Weight: 2500 kg

Daily feed quantity: 10,000 - 12,000 kg depending on feed material

Mixer volume: 2.2 m³ / up to 800 kg

Travelling speed: up to 13 m/min

Navigation: Magnets embedded in the floor at 1-metre intervals

Magnet diameter: 5 mm, no steel plate needed on the floor

Battery operated: 48V battery, cooling and heating mats integrated into the battery

Charger terminal: Drive-in intelligent charging station for consumption-optimised charging cycles, connected load 400V/16A

Gradient: up to 10%

Filling: Feed kitchen customer-optimised for feed components & daily feed volume, basic ration, concentrates, mineral feed, liquid components

Trough width: to one side 2500 mm, to both sides 3000 mm upwards (4500 mm needed to turn around)

Options: Battery expansion, magnetic separator, second charging station, feed height measurement

Power consumption: Approx. 20 kWh/day (farm with 50 dairy cows)

Media: